top of page

American Mud Pumps Blog

Drilling mud systems that boost rig performance

Drilling mud systems combine high-performance mud pumps, solids control equipment, and fluid handling infrastructure to ensure proper circulation, pressure control, and cuttings removal.

AMP

Feb 183 min read

Drilling mud challenges and equipment in Venezuela

Drilling operations in Venezuela are shaped by a combination of heavy crude reservoirs, variable formations, and legacy infrastructure that demands robust, proven solutions.

AMP

Feb 92 min read

Who manufactures mud pump spare parts? a practical comparison

When a mud pump fails, the real cost is rarely the part itself, it’s the downtime, lost drilling time, and emergency decisions that follow.

Yet many decision-makers still choose mud pump spare parts without fully understanding who manufactures them and how those options truly compare.

AMP

Jan 272 min read

Checklist to verify mud pump parts quality before buying

Buying mud pump parts is rarely about price alone. In drilling operations, a liner, valve, or piston that looks correct on paper can still fail early if quality control is weak.

The cost of downtime, safety risk, and lost circulation far outweighs any short-term savings. This guide focuses on mud pump parts quality control using a practical, checklist-based approach that buyers can apply before placing an order.

AMP

Jan 202 min read

Oilfield Rig readiness checklist for the new drilling year

The start of a new year is more than a calendar change for an oilfield rig, it’s a strategic reset.

After months of continuous drilling, pressure cycles, and exposure to harsh environments, the first quarter is the best moment to reassess operational readiness before activity accelerates again.

AMP

Jan 52 min read

Ceramic liners: the new standard in high-pressure drilling

As drilling programs push deeper and harder, reliability in every component matters.

Ceramic liners aren’t simply an upgrade, they are quickly becoming a best practice for rigs that operate under demanding pressures and abrasive conditions.

The evidence is clear: better wear resistance, stronger pressure performance, lower operating cost, and proven results in the field.

AMP

Dec 9, 20252 min read

Quick guide to choosing the best mud pump for O&G

Selecting the right mud pump is more than a purchasing decision: it’s an operational strategy.

In drilling environments, where abrasive fluids, high pressures, and continuous circulation are the norm, choosing the wrong pump can lead to premature failures, costly downtime, and safety risks.

AMP

Dec 3, 20252 min read

How to extend Mud Pump life with zirconia liners

How to Extend Mud Pump Life with Zirconia Liners

Advantage: Immediate Reduction in Wear & Failures

Every drilling operation fights the same enemy: abrasion, heat, and pressure that slowly destroy the mud pump from the inside. A standard liner can survive the job… but a zirconia liner changes the economics completely. By resisting the aggressive solids inside your mud, zirconia dramatically reduces wear from day one — giving your pump longer life and fewer

AMP

Nov 18, 20252 min read

Technology meets Talent: the future of offshore operators

Working on an offshore platform has always demanded resilience, skill, and precision.

For decades, operators have been the backbone of oil and gas production at sea.

AMP

Sep 30, 20252 min read

Why Pulsation Dampeners are essential for Mud Pump systems

In high-pressure mud pump operations, precision and reliability are everything.

Pumps working under extreme conditions must handle abrasive materials, high flow rates, and fluctuating pressures on a daily basis.

One of the most effective ways to protect these systems is by using pulsation dampeners, a component often underestimated but vital for the long-term health of the pump and connected equipment.

AMP

Sep 3, 20252 min read

New materials, new advantages: the revolution in Mud Pumps

In the drilling industry, performance and reliability are non-negotiable.

Every hour of operation is tied to high costs, and every breakdown can trigger a chain reaction of delays.

Over the last decade, mud pump design and manufacturing have undergone a significant transformation, not just in operating performance, but in the very materials from which these machines are built.

AMP

Sep 2, 20252 min read

Upstream: foundation of the global oil and gas supply chain

In the oil industry, upstream represents the stage where it all begins: the exploration and production of crude oil and natural gas.

AMP

Aug 12, 20252 min read

Smart stocking: plan ahead to extend Mud Pump lifespan

In the oil and mining sectors, mud pumps work under intense and abrasive conditions, where even a few hours of downtime can translate into massive operational losses.

Yet, many operations still wait until a part fails before acting, exposing themselves to supply chain delays, budget overruns, and unnecessary stress.

AMP

Aug 7, 20252 min read

Understanding the Power End Assembly: beyond the Crankshaft

In the world of mud pump operations, the Power End Assembly (PEA) is often referred to as the "heart" of the machine.

It's where rotational energy is generated and transformed into the linear force that drives fluid through the pump.

AMP

Jul 29, 20252 min read

What really wears down a Mud Pump, and how to slow it down?

If you’ve ever had to shut down operations because of a failed mud pump part, you know how fast costs can pile up.

AMP

Jul 23, 20252 min read

Which Valve is right for your mud pump?

Choosing the right valve doesn't just ensure the pump runs correctly, it directly impacts productivity, maintenance costs, and operational efficiency.

That’s why it’s critical to use durable, high-pressure valves precisely engineered to fit your equipment.

AMP

Jul 16, 20252 min read

Skill and grit in the hands that keep Mud Pumps running

Mud Pump maintenance professionals rarely get public recognition.

But among their peers, there’s deep respect. They know the value of every weld, every torque check, every swap done right the first time.

AMP

Jul 8, 20253 min read

The mechanical parts that keep your Mud Pump running

In drilling operations, mud pumps are vital. But when it comes to maintenance or sourcing spare parts, attention usually goes to the most common components: liners, valves, and pistons.

AMP

Jul 2, 20253 min read

Mud Pump Parts that fit: cut downtime and boost safety

In drilling operations, precision is critical, and when it comes to mud pump parts, compatibility and quality can define the success of an entire project.

AMP

Jun 24, 20252 min read

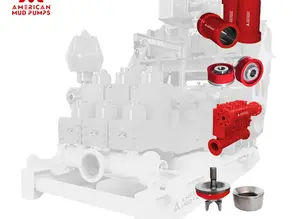

The Fluid End: the heart of a Mud Pump’s performance

In the world of oil and gas drilling, reliability is everything. At the center of that reliability lies the fluid end of a mud pump.

AMP

Jun 19, 20252 min read

Frequently asked questions about Mud Pump Pistons

Focusing specifically on mud pump pistons, professionals in the oil industry often raise questions that reflect the unique challenges of handling abrasive, viscous, and solids-laden fluids.

AMP

Jun 12, 20253 min read

How Liner design affects pump efficiency and maintenance cycles

In the high-pressure world of oil and gas drilling, every component in your mud pump must perform with precision—and few parts play a more critical role than the liner.

AMP

May 28, 20252 min read

Spot trouble early: save your Mud Pump from costly failure

Ignoring maintenance to mud pump, is one of the fastest ways to shorten your pump’s life—and increase your long-term costs.

AMP

Apr 2, 20252 min read

Quality Parts + Expertise: the formula for a lasting mud pump

Quality Parts + Expertise: the formula for a lasting mud pump

AMP

Feb 12, 20252 min read

bottom of page